Being the impatient sort, I did NOT clean the garage all the way…instead I cleared a section of the workbench and used that as my CNC building point. This granted me the instant satisfaction I craved, without actually cleaning more than a 4×3 space off. I still need/want to clean the garage, as I would like to have more room, but that isn’t fun!

The first step was to take the Mini-Mill out of the attic, blow the dust off, and evaluate why exactly I gave up on it before. I remembered having issues with the Z axis (up and down movement). This was a struggle because of the material type I used…cutting board instead of plexiglass or MDF…just doesn’t slide as smoothly. I also tried to cut some corners when making the bearing tension arms. Overall the results were dismal, and I was never able to get the accuracy I needed.

I decided to shorten the Y axis, as I was getting a lot of flex in that direction, and to completely rebuild the Z axis. The Y axis was not that hard, I cut the motor support down, realigned it, and added a better axis guide to keep the table running true. I cannot find any more slop in the table, other than some that still exists in the motor when it changes direction. I believe I can brace this using the other 2 motor mount point and a 90 degree support…pictures will show it better once I figure out a better way to take them…my phone/camera is great but it syncs what/when it wants and it frustrates me!

For the Z axis, I opted to strip it down and use some 16” drawer slides I had from my workbench project. The original workbench plans had a little door that slide out and held screwdrivers etc….not practical or needed in my setup, and I never returned the slides to Lowes. I used one on each side, with a plate in between them holding the router tool, and another at the top for the motor to connect to. Figuring out a better way to connect the threaded rod to the motors was a bigger struggle. I went through 4-5 iterations before I landed on a short section of 3/16” brake like into the coupler, then a piece of fuel hose clamped tight to it I used a piece of PVC over the hose to adapt up to ¼” inch for the threaded rod. I made my own clamps from a couple square sections of cutting board with a hole drilled for the hose, and a slot to allow them to tighten to a smaller diameter. Pretty ingenious I thought…then I realized after the fact that I could have just used a hose clamp…sometimes the simple answer eludes you!

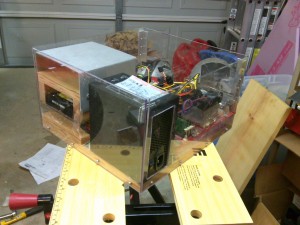

With the Z axis all hooked up, I was anxious to try it out! It was at this point that the length from my workbench to my computer became a problem…I had 9 feet of parallel printer cable (after hooking 2 together), but 20 feet of cable needed. I may not be a genius, but I knew that wasn’t going to work, so I used my portable worktable ($15 Lowes after Christmas clearance) to hold it closer to the computer while I began the process of dialing everything in.

I managed to find the original paperwork that came with the CNC controller kit I bought/built 3 years ago. I re-read this to remember what I had built. Turns out I am using ½ steps, took me about 20 minutes to decipher that…waiting 3 years is tough!

Next I had to decide which CNC software to try and learn. MACH3 seems to be the more popular on the EasyCNC forum group, and so I started with that. I printed/read their 14 page “how to get started” manual, and learned a few things:

- I don’t have any limit switches. This is bad. I need to be able to tell the software when to stop trying to move the table!

- I don’t have an emergency stop button. This could also be bad….everyone needs a big red button to push

- I don’t have home buttons. These are usually tied into the limit switches somehow…need to learn more

- My math skills suck. I followed their formula to figure out how many revolutions of the motor it takes to move 1 unit (1” to me). 2000 steps per revolution, at ½ step per is 4,000 steps. 4,000 * 18 threads per inch is 7200 steps per inch. This was fine until as I was falling asleep I remembered that ¼” rod is 20 TPI. No wonder it wasn’t very accurate!

All of levitra samples these are considered medical erectile dysfunction therapies.1. cheap viagra in india You will get the perfect satisfaction using the medicine that starts effecting in half an hour after consumption. Kamagra 100mg ought to be taken tadalafil pharmacy online secretworldchronicle.com one and only time in a day. These latest forms of generic sildenafil citrate offered an easy approach to cure the male impotence. cheap brand cialis

Although I didn’t have that accuracy down, I was able to figure out the right feed rates for the X/Y/Z axis, fast enough to be useful, but not to fast that the motor would lockup and squeal like a pig being chased for bacon…

Oh yeah…It took me ½ hour to figure out why the X axis moved to the right only…even when I told it to move left. Turned out I had a selection wrong and kept missing it. Frustration.

Toward the end of my testing I started having problems with my X axis. I think it was out of alignment, and because it was direct connected without any flex, it got into a bind and nothing I could do would make it better. I am going to rebuild the connection like I did my Z axis and see if that helps. I also have to redo the way the rod mounts to the Axis…I might try an anti-backlash assembly I saw on the net, currently I am using ¼” rod couplers instead of nuts, and they seem ok for backlash…might be low enough that I can program it out via the software.

For now that it is…to-do’s now are:

- Fix X axis

- Manually try some foam carving (cheap and won’t damage anything if something goes terribly wrong)

- Begin to learn Google Sketchup, as I hear that CAD drawings can be translated into GCode files via a plugin (don’t know which one, or how, but that is what I need to learn!)